Challenge

Solution

Insufficient flexibility of production system

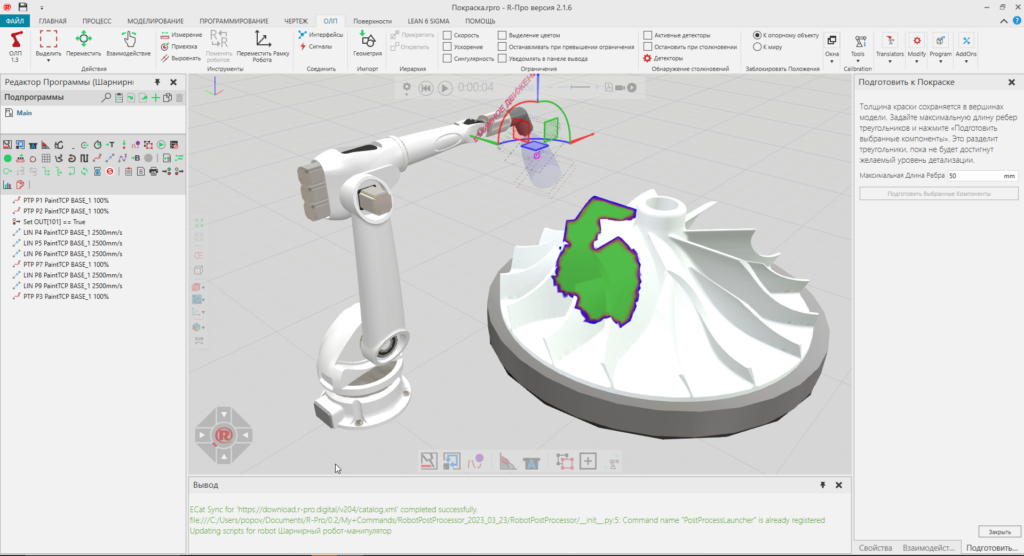

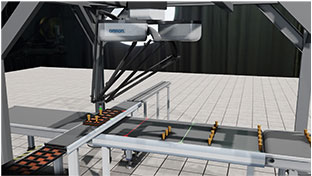

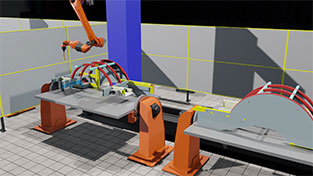

3D modelling

Insufficient time, material resources and qualified personnel to carry out activities to improve the efficiency of production and technological processes.

The Rational Production software product contains functionality for 3D modelling and simulation of production and technological processes.

Test various optimisation hypotheses in the shortest possible time through a user-friendly and easy-to-use graphical interface, while built-in analysis tools help you select the most effective option among the available ones.

Complexity of modernisation project approval

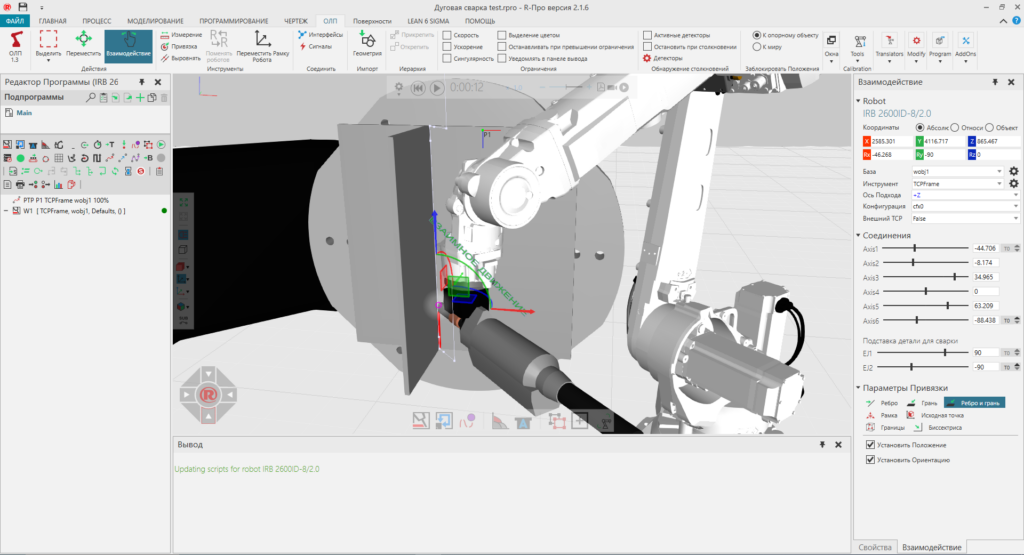

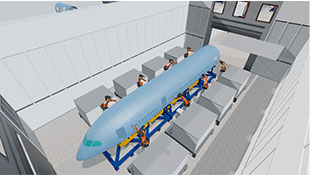

Visualisation

The process of interaction between different services at the enterprise in the decision-making process can be significantly complicated due to the use of specific tools that do not unambiguously prove the effectiveness of the proposed solutions, and the disparate professional interests of employees.

The Rational Production software product contains functionality for visualising the results of modernisation projects.

The digital twin allows to unite specialists from different areas working together on the project at each stage of the life cycle of a complex solution. The results obtained can be presented in the form of a clear interactive visualisation showing in detail all processes and system elements, as well as the results of data analysis, which has a positive impact on the decision-making process.

High cost of making changes to the production process

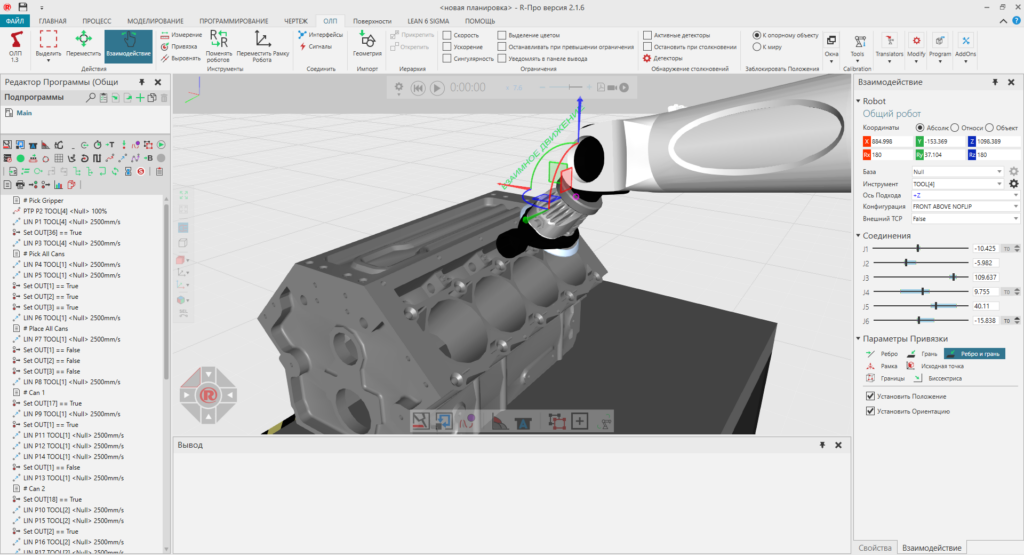

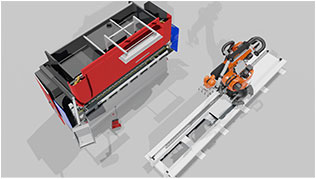

Virtual testing

In order to test the optimisation hypothesis, it is necessary to make changes in the technological processes on real equipment, as well as to implement them in the operation of a real workshop. The actual results of the changes can be obtained only after the above-mentioned activities have been completed.

The Rational Production software product contains functionality for virtual testing and commissioning.

Test the operation of your equipment before you buy and commission it, and adjust its operation and evaluate its performance in a digital twin, significantly reducing the losses your business could incur.

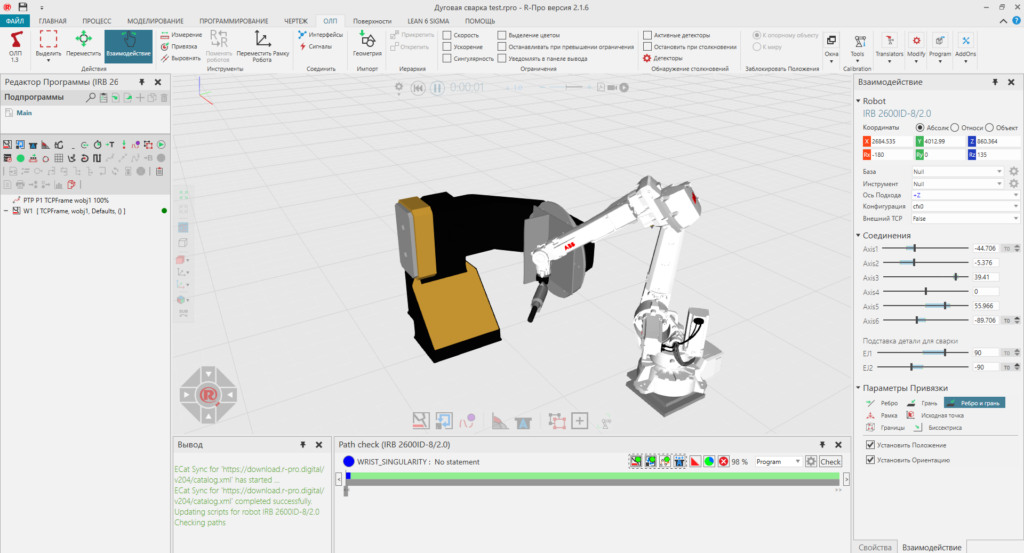

Long new product development cycle

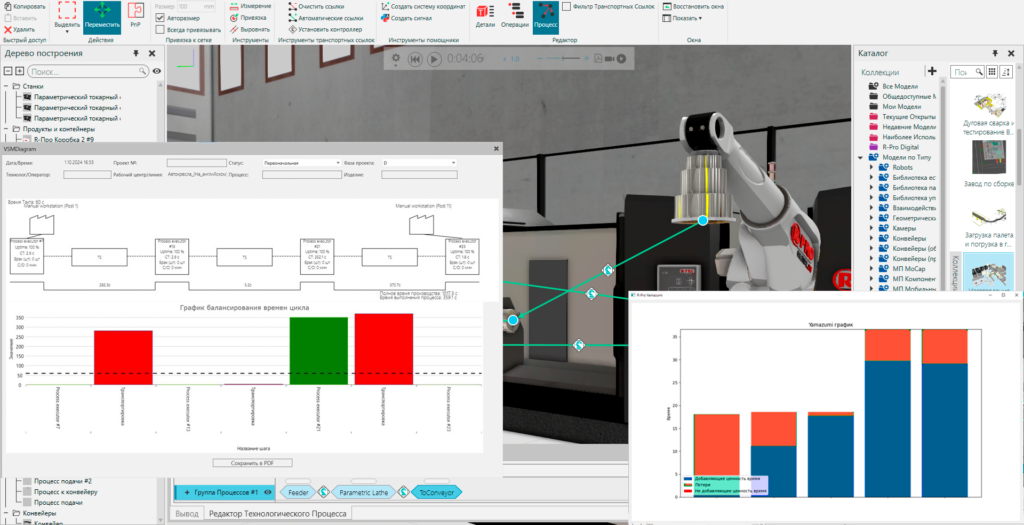

Simulation analyses

The existing mechanisms do not allow for accelerated modernisation of production facilities and changes in production technology.

The Rational Production software product contains functionality for simulation modelling.

Make rapid changes to product technology by analysing WHAT-If scenarios, accelerated design and high accuracy of simulation model predictions.

Low continuous operation of equipment

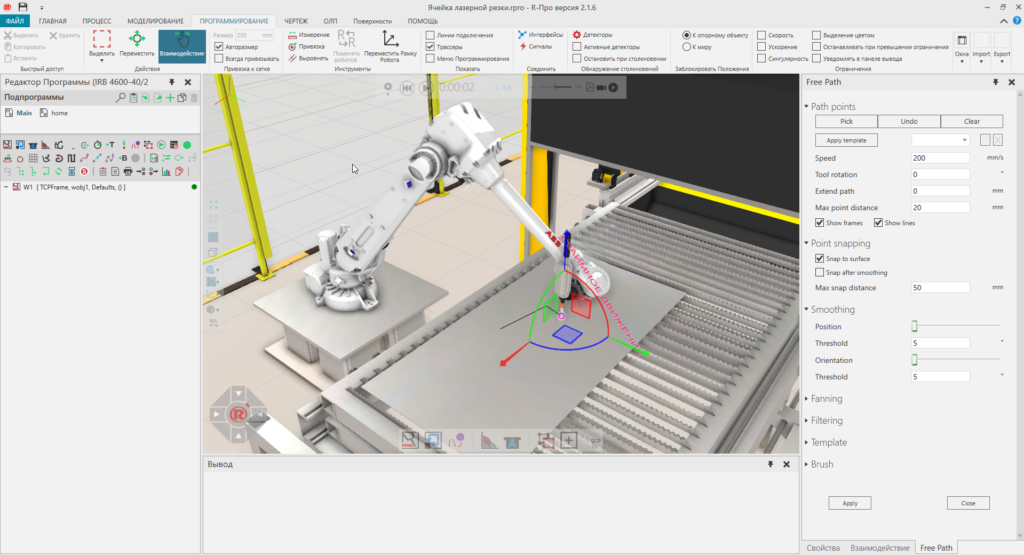

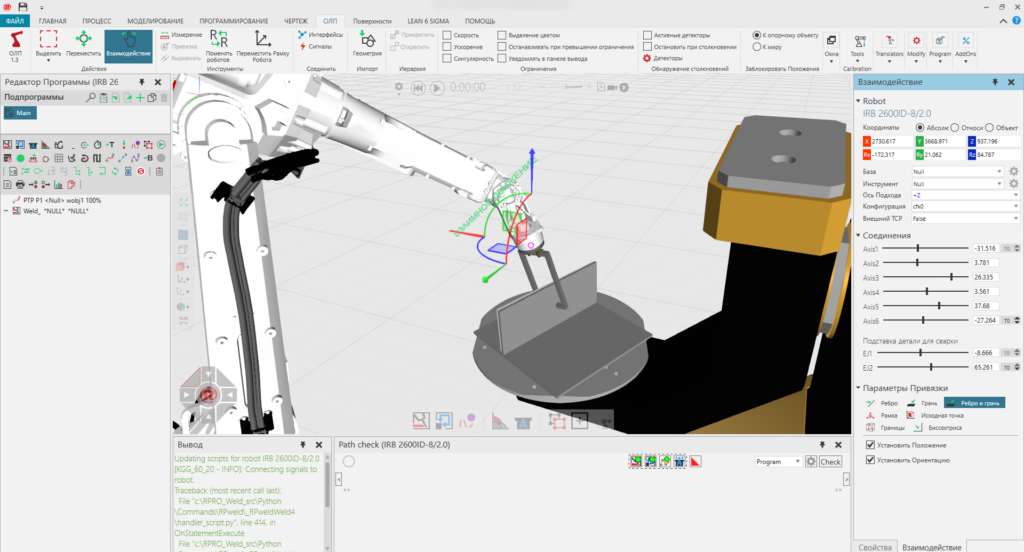

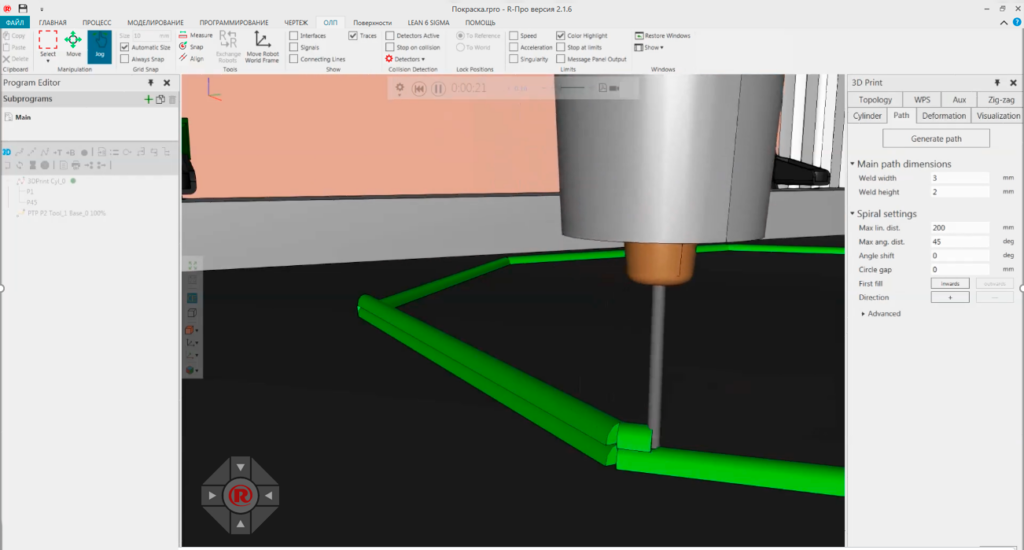

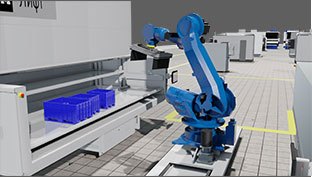

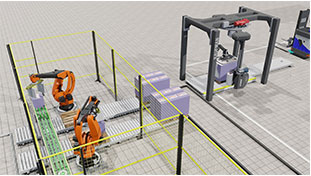

Offline programming

Changeover of process equipment and RTC is necessary for all enterprises with a wide product line. At the same time, programming equipment for new tasks on the shop floor leads to a significant loss of useful time due to the need to take equipment out of operation for the changeover period.

The Rational Production software product contains functionality for offline programming of RTC and equipment.

Create programs to control process equipment and robots with complex motion paths without stopping production, and post-processing tools allow you to transfer the control programme to machine controllers in two clicks.

ANY QUESTIONS?

WHY CHOOSE SUSTAINABLE PRODUCTION?

Rational Production is a Russian solution designed to create digital twins of production.

A digital twin of production is a virtual copy of a separate production cell, workshop or plant as a whole, reflecting all the technological parameters and behaviour of the real object.

The digital twin of production allows to optimise technological processes in a simulation environment without stopping production, and to make changes much faster and safer than in experiments on real objects.

YOU WILL GET

Operational testing and debugging of equipment in a digital environment

Minimising costs by testing optimisation hypotheses in a virtual environment

Cost reduction through process optimisation

Quick adaptation to market changes through accelerated design

Reducing employee training costs through the use of VR simulators

Powerful marketing and sales tool through detailed visualisation

APPLICATION IDUSTRIES | ROBOT BRANDS

FUNCTIONS

FUNCTIONAL MODULES

SYSTEM REQUIREMENTS

Minimum System Requirements:

Recommended System Requirements:

Important: it is recommended to connect Internet access when activating the product and downloading the components catalogue.

Running the Rational Manufacturing software on a virtual machine or accessing it via remote desktop is not supported.

Clients

START 3D MODELLING NOW

Services

Engineering

Implementation of complex projects for the creation of digital twins of production

Training

A wide range of educational courses in the field of digital technologies

Support

Assistance and counselling on any questions on the use of the software

Customised developments

Software development on request